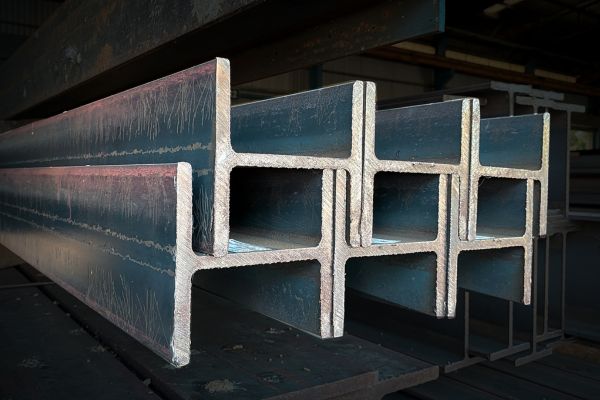

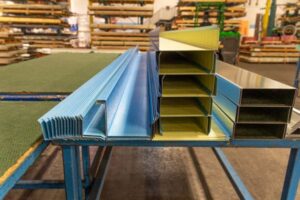

C-Purlins are a type of structural steel component that plays a vital role in supporting roof and wall systems in a wide range of construction projects. Characterized by their “C” shape, these purlins provide essential support for cladding materials, helping to create durable, reliable frameworks that stand the test of time. Widely used in both commercial and residential construction, galvanized C-Purlins are renowned for their versatility and strength, making them a preferred choice for constructing buildings, warehouses, and other structures.

In the fast-paced world of construction, especially with the growing demand for quicker project turnarounds in 2025, C-Purlins are gaining more attention for their ability to streamline building processes. Their prefabrication capabilities, lightweight design, and ease of assembly significantly reduce construction time and labor costs, allowing projects to be completed more efficiently and within tighter deadlines. By understanding the unique advantages of C-Purlins, construction teams can make informed decisions that help them achieve faster, more cost-effective results while maintaining structural integrity and performance.

How C-Purlins Contribute to Faster Project Turnarounds

Prefabrication and Standardization

C-Purlins are pre-manufactured in controlled environments to precise dimensions, which means they arrive on-site ready for installation with minimal modifications required. This prefabrication reduces the need for cutting, welding, or adjustments during the construction process, allowing crews to move quickly from one stage to the next. The standardization of C-Purlins also ensures consistent quality across all components, which streamlines installation and reduces the potential for errors. By relying on standardized sizes and shapes, construction teams can expect smoother coordination and fewer delays, ultimately speeding up project timelines.

Lightweight Yet Strong

Despite their strength, C-Purlins are remarkably lightweight, making them easy to transport and handle on-site. This combination of lightness and strength is crucial for speeding up the construction process. The reduced weight lowers transportation costs and allows workers to handle larger quantities of purlins with less manpower and equipment. Furthermore, C-Purlins maintain excellent structural integrity even under heavy loads, ensuring that the finished framework remains durable and reliable while supporting the overall speed of assembly.

Easy Assembly and Installation

C-Purlins are designed for easy alignment, bolting, or welding, which significantly reduces installation time compared to more complex steel components. The simplicity of the process allows construction teams to work quickly and efficiently, without requiring specialized skills or equipment. Whether it’s aligning the purlins along the roof structure or securing them to the supporting framework, the use of basic tools and straightforward techniques further minimizes time spent on-site. The result is a rapid C-Purlin installation process, allowing construction projects to progress without unnecessary delays.

Reduced Labor Costs and Downtime

For the C-Purlin price, one of the biggest advantages of using C-Purlins is their ability to reduce labor costs and project downtime. Because these components are easy to handle, transport, and install, fewer workers are needed to complete the job, and the amount of time spent on each phase of the construction process is reduced. The faster assembly and quicker project completions also translate to reduced downtime, meaning construction projects can move ahead of schedule. This acceleration not only saves money but also leads to quicker occupancy or use of the facility, maximizing the return on investment for building owners.

Applications for C-Purlins in Construction Projects

C-Purlins are incredibly versatile components, widely used in various construction applications due to their strength, lightweight nature, and ease of installation. Below are some of the key areas where C-Purlins are commonly utilized:

- Roofing

C-Purlins are a staple in roofing systems, providing essential support for roof panels and sheeting. Their ability to bear heavy loads while maintaining structural integrity makes them ideal for creating stable, durable roofing structures. Often used in conjunction with other steel components, C-Purlins are installed at regular intervals to form a framework that holds the roofing material securely in place. Their lightweight nature allows for easier handling and quicker installation, reducing overall project time and labor costs.

- Wall Frames

In addition to roofing, C-Purlins are also used in the construction of wall frames. These purlins provide the necessary support for the cladding or sheathing material, ensuring the structure remains rigid and stable. Their uniformity and standardization make them particularly well-suited for creating consistent, reliable wall frames that meet the design requirements of various construction projects. Whether used for exterior walls or interior partitions, C-Purlins are essential for creating strong, durable wall structures.

- Mezzanine Floors

C-Purlins are frequently used in the construction of mezzanine floors, where they support flooring systems and contribute to the overall stability of multi-level structures. Mezzanine floors are commonly found in warehouses, industrial buildings, and commercial facilities, providing additional space without the need for a full second story. C-Purlins’ ability to bear significant loads and span long distances without excessive support columns makes them ideal for these types of applications, enabling efficient use of vertical space while ensuring safety and durability.

Popularity in Commercial Buildings, Warehouses, and Industrial Facilities

Due to C-Purlin strength, affordability, and ease of installation, the material has gained immense popularity in commercial buildings, warehouses, and industrial facilities. In commercial buildings, C-Purlins are used in both roofing and wall applications to create stable frameworks that can support heavy loads. In warehouses and industrial facilities, C-Purlins are often used for large-span roofing and mezzanine floors, providing the flexibility and strength required for complex building designs. Their widespread use in these types of buildings is a testament to their ability to enhance both the speed and quality of construction, making them an indispensable choice for modern construction projects.

Looking Ahead: C-Purlins in 2025’s Construction Trends

As we move toward 2025, the construction industry is increasingly focused on projects that demand rapid turnarounds, sustainability, and cost efficiency. C-Purlins will continue to be a key element in meeting these evolving demands, offering unique advantages that align with these trends.

- Fast Turnarounds

The need for faster project completion is expected to grow in 2025, driven by the rising demand for commercial, residential, and industrial spaces. C-Purlins, with their prefabrication and lightweight properties, will remain crucial in shortening construction timelines. Their ease of handling, quick assembly, and minimal need for on-site adjustments will continue to be a game-changer in expediting the construction process.

- Sustainability

Sustainability will remain a top priority in 2025, and C-Purlins are well-positioned to contribute to more eco-friendly construction practices. Made from recyclable steel, C-Purlins are a sustainable option that reduces environmental impact, aligning with green building initiatives. Their lightweight nature not only reduces material waste but also minimizes transportation costs and fuel consumption. Additionally, their durability ensures longer-lasting structures, contributing to the overall lifecycle sustainability of a building.

- Cost Efficiency

Cost efficiency will continue to be a driving factor in construction decisions in 2025, especially in a post-pandemic economy where budget constraints are still prevalent. C-Purlins offer a cost-effective solution by reducing material wastage, minimizing labor requirements, and shortening construction time. With their low maintenance needs and ability to withstand harsh weather conditions, C-Purlins will help builders and developers meet tight budget requirements while ensuring long-term value for both the building owners and the environment.

Achieve Faster Project Turnarounds with He-Max Industrial’s C-Purlins!

Ready to accelerate your construction projects in 2025? He-Max Industrial Corporation is a C-Purlins supplier with a range of high-quality C-Purlins-the perfect combination of durability, strength, and lightweight properties, ensuring smooth and fast installations for your construction needs.

At He-Max, we are committed to providing C-Purlins in the Philippines that meet the highest industry standards, helping you maintain structural integrity while saving time and costs. With competitive pricing, reliable delivery, and expert support, we ensure that your projects stay on track and on budget.

Contact us today for a customized quote and let us be your trusted partner in achieving faster, cost-effective construction results!

For more information or inquiries, feel free to contact us at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial