In any building, a strong framework is essential for stability and support, especially for roofing materials like metal sheets or tiles.

Structural steel purlins excel in this role, offering durability, impact protection, and lightweight versatility. They reinforce the structure and ensure long-lasting reliability for various building designs.

C and Z Purlins are vital in modern construction, offering versatile structural support for roofing and wall framing in residential and commercial buildings.

Many homeowners and building contractors now choose structural steel purlins for their construction needs, particularly for their durability and longevity. Finding a reliable and trusted C Purlin supplier can help you

What are Purlins?

Purlins are horizontal beams that provide structural support, commonly used in metal buildings but also found in wooden structures.

Steel building purlins are commonly used in pre-engineered buildings to support roofs. Made from cold-formed steel, they create a horizontal diaphragm to bear roof and deck loads. Modern warehouses, parking lots, facilities, and even residential spaces benefit from steel purlins due to their superior properties.

Choosing the right purlin can be challenging. To start, purlins are classified into two types: C Purlins and Z Purlins.

While both are commonly used in residential and commercial construction, they differ in shape, installation, and application. C Purlins are ideal for situations where the purlin needs to rest on a flat surface, while Z Purlins are better suited for overlapping arrangements, especially for longer spans.

All About C Purlins

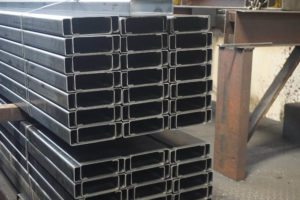

C purlins, shaped like the letter “C,” are lightweight steel purlins commonly used to support walls and floors. Also known as channel section purlins or U-sections, C-sections are mono-symmetrical and cannot be lapped.

Their stable shape ensures easy packaging and transportation. These purlins are widely used in clear-span designs due to their high stability.

C-section purlins are designed to form the walls and floor joists of a building shell, making them ideal for supporting beams in mezzanine flooring., These versatile purlins can also be used for door framing, roof trimming, window trimming, parapet rails, and side rails.

Read to know more about how C Purlins can be the perfect fit for your construction needs.

Z Purlins 101

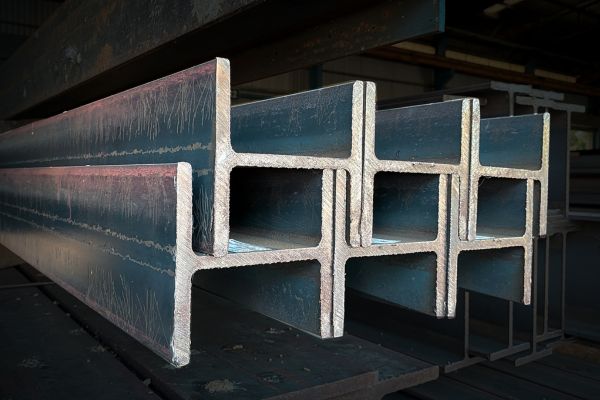

Z purlins are horizontal beams that form the roof and wall joists of a building structure. Named for their “Z” shape, these purlins offer stronger and more stable connections due to their overlapping design, making them sturdier than C purlins.

Z purlins are commonly used in large-scale structures due to their superior strength. Z-section purlins are also ideal for flat or slightly sloping roofs.

Their unique shape provides greater rigidity and stability compared to C-section purlins, allowing them to handle heavier loads. Z-section purlins also offer a tighter fit on rafters, enhancing overall stability once installed.

Key Differences Between C and Z Purlins

Shape and Profile

C Purlins are lightweight steel purlins that have a simple “C” shape, making them suitable for straightforward applications like supporting walls and roofs. Their design is basic and often used where minimal complexity is needed.

Z Purlins features an angled “Z” shape, Z purlins are designed for interlocking and overlapping installations. This shape allows for better connection and alignment between purlins, providing additional stability in more complex structures.

Installation

C Purlins are known for their ease of installation, C purlins are ideal for simpler structures where quick setup and minimal adjustments are required. They can be placed without the need for interlocking, making the process more straightforward.

Z Purlins are designed for interlocking, Z purlins provide stronger connections between sections. This feature makes them ideal for longer spans and heavier structures, as the interlocking design enhances overall strength and stability during installation.

Strength and Load Capacity

Z Purlins generally outperform C purlins in terms of load-bearing capacity due to their interlocking design and thicker profile. This makes them the preferred choice for heavy-duty applications where higher load requirements and greater structural integrity are necessary.

While C Purlins are strong and durable, they have a lower load-bearing capacity compared to Z purlins. They are more suited for lighter loads and less demanding structural requirements.

Best Fit for Applications

C Purlins are Ideal for smaller, lighter structures such as walls, single-span roofs, or residential buildings. They work best in situations where simplicity and cost-effectiveness are priorities.

Z Purlins are best suited for large-scale projects or commercial buildings that require longer spans and greater strength. They are perfect for applications where stability and durability over extended distances are essential, such as in industrial or agricultural buildings.

Choosing the Right Purlins for Your Project

Choosing the right metal building purlins for your project involves deciding between C and Z purlins. Each has its advantages and disadvantages, making it essential to understand both to make the best choice. Here are some tips for selecting the right purlins for your construction needs:

- Select the Right Material – Purlins support large roof decks and rely on rafters, walls, or steel beams for stability. The material plays a crucial role in ensuring durability, environmental sustainability, and structural safety.

- Choose the Ideal Purlin Type – Your choice should align with construction requirements and roofing quality. Z and C purlins differ in their angles. The C purlin features a 90-degree angle, while the Z purlin has an angle of less than 90 degrees. As a result, Z purlins are more flexible than C purlins, making them suitable for a wider range of applications.

- Ensure Proper Installation – Install purlins horizontally under metal roofs, mounted on top of rafters with a felt underlay or vapor barrier. It’s important to remember that C and Z Purlin installation is always best left to the experts.

- Choose a Reliable Supplier – Ensure your purlin supplier offers high-quality materials and adheres to industry standards for optimal performance and longevity. It’s advisable to reach out to multiple suppliers for price comparisons. However, don’t make price the sole deciding factor. If necessary, visit their sales office or speak with a sales representative to ensure you’re working with a reliable supplier.

He-Max Industrial Corporation: Your Trusted C Purlins Supplier

Gearing up to supercharge your construction projects in 2025? Look no further! He-Max Industrial Corporation is a trusted supplier of high-quality C Purlins in the Philippines. Our C Purlins offer the perfect balance of durability, strength, and lightweight properties, making them an ideal choice for your construction needs.

At He-Max Industrial Corporation, we are committed to providing C and Z Purlins that meet the highest industry standards. As a trusted C Purlins supplier, we offer various sizes to meet your project needs.

Contact us today to explore our range of C and Z purlins or how to avail our comprehensive range of services.

For more information or inquiries, feel free to contact us at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial