Selecting the right tubular steel is crucial for ensuring strength, durability, and efficiency in various applications. Whether you’re working on a high-rise building, reinforcing an industrial system, or stocking your hardware store, choosing the proper tubular steel is a critical decision that affects both performance and cost. This guide will help you understand the essential considerations when selecting tubular steel sizes in the Philippines, as well as where to source high-quality materials for your project.

Let’s explore the different types of tubular steel, how to match them to specific applications, and what factors to prioritize when selecting a supplier.

Key Takeaways:

- Choosing the right tubular steel ensures strength, durability, and cost efficiency.

- Types include round, square, and rectangular tubes, each suited for specific structural needs.

- Seamless tubes are stronger for high-pressure uses, while welded tubes are more affordable for general applications.

- Stainless steel resists corrosion, carbon steel is strong and cost-effective, and galvanized steel withstands rust.

- Key factors: load capacity, environmental resistance, and customization options.

- Tubular steel is used in construction, manufacturing, and automotive for its versatility and durability.

- Reliable suppliers ensure quality, customization, and on-time delivery.

Importance of Tubular Steel

Tubular steel is a fundamental material across many industries—including construction, manufacturing, automotive, and infrastructure. Known for its high strength-to-weight ratio, structural versatility, and durability, tubular steel is commonly used for frameworks, pipelines, supports, railings, machine parts, and more.

Whether in the form of round, square, or rectangular tubes, this material provides structural integrity that helps ensure safe, reliable, and long-lasting results in various environments. More importantly, selecting the correct type, size, and material of tubular steel can greatly influence your project’s performance and overall budget.

Making the wrong choice can lead to structural failure, costly repairs, or excessive material waste. That’s why understanding the various specifications and applications of structural steel tubing, carbon steel tubing, and stainless-steel tubes is key to project success.

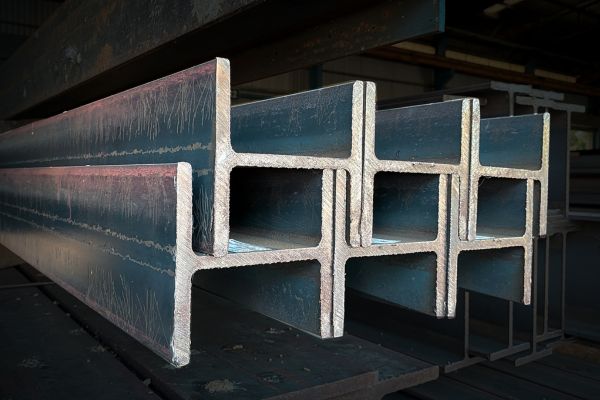

Types of Tubular Steel and Their Applications

Tubular steel is a versatile and durable material used in a wide range of industries and applications. Whether for construction, manufacturing, or industrial purposes, selecting the right type of tubular steel is crucial for ensuring strength, stability, and longevity. In this section, we’ll explore the different types of tubular steel and their common applications to help you make informed decisions for your projects.

1. Round, Square, and Rectangular Tubes

Tubular steel is manufactured in different cross-sectional shapes, each serving specific structural functions:

- Round Tubes are commonly used in railings, fencing, and plumbing systems. Their circular shape provides uniform strength under pressure, making them ideal for transporting fluids or supporting curved structures.

- Square Tubes offer uniform strength along all axes, making them perfect for columns, braces, and frames. They are widely used in construction scaffolding, furniture frames, and architectural structures.

- Rectangular Tubes are often chosen for applications requiring a flat surface and strong support along a specific axis. These are ideal for trailers, building supports, signposts, and general framing applications.

Each shape has its unique benefits based on load distribution, ease of installation, and design compatibility.

2. Seamless vs. Welded Tubular Steel

Another important classification is based on manufacturing:

- Seamless Tubular Steel is formed without a welded seam, making it stronger and more uniform in structure. It’s commonly used in high-pressure applications such as hydraulic systems, oil and gas pipelines, and automotive parts. Although more expensive, its superior performance justifies the cost in critical use cases.

- Welded Tubular Steel, on the other hand, is manufactured by welding steel plates or coils. While it may have slightly reduced strength at the weld seams, it is more cost-effective and sufficient for general structural purposes such as fencing, framework, and light construction.

Understanding the trade-offs between cost and performance can help you choose the right product based on project requirements.

3. Material Options: Stainless Steel, Carbon Steel, and Galvanized Steel

Choosing the right material is just as important as selecting the correct shape and manufacturing process. Here are the most common materials:

- Stainless Steel Tubes – Known for exceptional corrosion resistance, stainless steel is best for environments with high moisture, chemicals, or salt exposure. It’s ideal for coastal construction, food processing, and chemical industries.

- Carbon Steel Tubing – This offers high tensile strength and affordability, making it suitable for heavy-duty applications like machinery, industrial frames, and support beams. However, it is more prone to rust if not properly coated.

- Galvanized Steel – Coated with a protective layer of zinc, galvanized steel resists rust and corrosion, making it ideal for outdoor applications such as fencing, scaffolding, and signage.

Each material has distinct advantages depending on the use case, environmental conditions, and longevity expectations.

Key Factors to Consider When Choosing Tubular Steel

Selecting the appropriate tubular steel for your project is essential to achieving durability, efficiency, and safety. With various types and grades available, making the right choice can be challenging. Whether you’re working on a construction project, manufacturing process, or industrial application, understanding the key factors to consider will help you choose the most suitable tubular steel for your needs.

Load Capacity & Structural Strength

Perhaps the most crucial factor is the load-bearing capability of the tubular steel. The steel must meet the project’s weight, tension, and pressure requirements without bending or breaking. This depends on:

- The tube’s wall thickness

- Its shape and size

- The material’s tensile strength

Always refer to local building codes or consult with engineers when selecting tubular steel for large-scale construction or heavy machinery.

Environmental & Corrosion Resistance

Consider where the tubular steel will be installed. Exposure to moisture, saltwater, chemicals, or extreme temperatures can degrade certain materials over time. Stainless steel and galvanized steel are highly resistant to corrosion and offer long-term durability with minimal maintenance.

In contrast, carbon steel tubing may require protective coating or paint when used in corrosive environments.

Customization Options

The right tubular steel supplier should be able to accommodate your project’s unique requirements. This includes:

- Custom-cut lengths and diameters

- Pre-painted or galvanized finishes

- Delivery and logistics support

If your project demands precision and flexibility, choose a supplier who offers full customization and technical assistance.

Industry-Specific Uses of Tubular Steel

Tubular steel is a fundamental component in a wide range of industries due to its strength, versatility, and durability. From construction to manufacturing, each sector utilizes tubular steel differently, tailored to specific demands and conditions. Understanding how tubular steel is used across various industries can help you choose the right type and grade for your project.

Construction & Infrastructure

Tubular steel is essential in structural applications like:

- Beams and columns

- Scaffolding and temporary supports

- Railings and safety barriers

- Roof trusses and frameworks

Its strength, ease of installation, and resistance to weather conditions make it a go-to material for builders and civil engineers.

Manufacturing & Industrial Applications

In industrial settings, tubular steel is used in:

- Machinery frames and conveyor systems

- Pipelines for gas, water, and chemicals

- Storage racks and support structures

Its versatility and strength allow it to adapt to a wide range of heavy-duty applications.

Automotive & Transportation

The transportation industry also relies heavily on tubular steel for:

- Vehicle chassis and body frames

- Roll cages and crash structures

- Exhaust and fuel systems

Its lightweight yet durable nature contributes to safety and fuel efficiency in automotive design.

Conclusion

Choosing the right tubular steel sizes in the Philippines is a decision that affects safety, durability, and overall project success. Whether you’re working on construction, industrial equipment, or automotive systems, understanding the types, materials, and specifications of tubular steel is essential.

Always assess the load requirements, environmental conditions, and customization needs of your application before selecting material. Working with a reputable tubular steel supplier ensures that you receive high-quality products, expert guidance, and on-time delivery.

Get High-Quality Tubular Steel from HE-MAX Industrial Corporation

Looking for a reliable source of tubular steel in the Philippines? He-Max Industrial Corporation offers a complete line of durable, premium-quality steel tubing for construction, manufacturing, and industrial applications. Our trusted clients include contractors, subcontractors, construction firms, hardware stores, electrical suppliers, and manufacturers across the country.

Our product range includes:

- Stainless Steel Tubes

- Carbon Steel Tubing

- Galvanized and Structural Steel Pipes

- Custom Cutting and Finishes

- Fast Delivery and Bulk Order Support

Partner with He-Max Industrial for high-quality steel solutions that keep your projects moving. Call us today at 0917-1158387 / 0925-8092196 for inquiries or visit our Contact Us page for a quote or consultation. Stay updated by following us on Facebook for the latest news and product offers.