Tubular steel is a vital material in construction, fabrication, and industrial applications, providing a unique combination of strength, durability, and versatility. Commonly used in building frameworks, support structures, and various other projects requiring robust materials, tubular steel plays a crucial role in everything from scaffolding and bridges to furniture and machinery. This guide explores the most common tubular steel sizes, including round, square, and rectangular shapes, along with their respective applications, to help you select the right material for your project.

Common Tubular Steel Shapes and Sizes

Round Tubular Steel

Round tubular steel is one of the most versatile and widely used forms. Round tubular steel sizes range from ½ inch to several inches in diameter, and wall thicknesses vary from thin gauges for light-duty applications to thicker walls for heavy-duty uses. Standard lengths range from 6 to 12 meters but can be customized to suit specific project requirements.

Round tubes are commonly used in scaffolding, where they provide strength and flexibility for temporary structures. They are also popular for fencing due to their durability and corrosion resistance. Additionally, round tubes are used in pipelines, handrails, and guardrails, offering both safety and aesthetic value. Their uniform shape makes them ideal for applications requiring even load distribution, such as structural supports and machinery frameworks.

Square Tubular Steel

Square tubular steel is commonly used in structural and framing applications due to its uniform strength and aesthetic appeal. Square tubular steel sizes in mm vary, from small sections of 20mm x 20mm for lighter-duty applications to larger structural forms of 200mm x 200mm or more for heavy-duty use. Wall thickness typically ranges from 1.5mm for lighter frames to 6mm or thicker for large-scale constructions. Lengths typically range from 6 to 12 meters, with custom sizes available.

This shape is ideal for constructing frames and columns, where its symmetrical form provides consistent load-bearing capacity. It is particularly effective for building industrial frames, support columns, and scaffolding. Square tubes are also commonly used in the fabrication of gates, fences, and barriers, offering both strength and clean, angular lines. Their versatility and strength-to-weight ratio make them ideal for both residential and commercial projects.

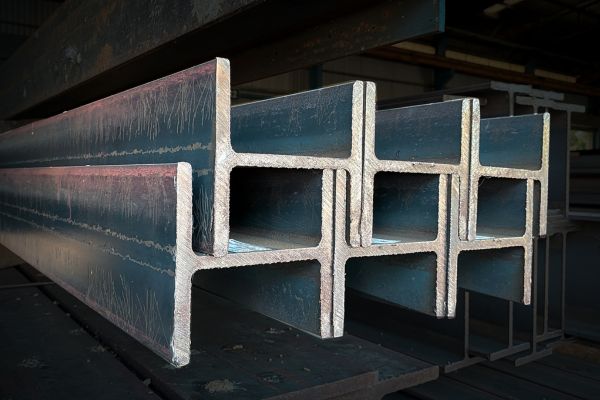

Rectangular Tubular Steel

Rectangular tubular steel is most used for heavy-duty applications requiring strength and stability. Common rectangular tubular steel dimensions range from 40mm x 20mm for smaller applications to 400mm x 200mm for larger structures. Wall thicknesses vary from 2mm for lighter uses to 12mm or more for high-strength structures. Standard lengths vary from 6 meters to 12 meters but can be customized.

Rectangular tubes excel in load-bearing applications, such as support beams, frames, and columns, thanks to their resistance to bending and twisting. They are frequently used in bridges, industrial buildings, and heavy-duty frames, where strength and space efficiency are critical. The large surface area of rectangular tubes allows for greater load-bearing capacity, making them ideal for demanding projects.

Factors to Consider When Choosing Tubular Steel Sizes

Load Capacity Requirements

Matching the size and shape of tubular steel to the load-bearing needs of a project is crucial for safety and performance. Larger diameters or thicker walls offer higher load capacities, making them suitable for heavy-duty applications. For instance, round or square tubes with larger sections are perfect for load-bearing frames or columns. Conversely, smaller sections are better for lighter structures like handrails or fencing. Understanding the distribution of load and specific demands of the project ensures the right choice of steel.

Weight and Durability

Wall thickness impacts both the weight and durability of tubular steel. Thicker walls provide more strength and stability, allowing the steel to endure greater forces and extend its lifespan, particularly in harsh conditions. However, thicker walls also increase the weight, which may affect handling and installation. Thinner walls reduce weight but may not offer the same durability. Striking the right balance between strength, weight, and durability is essential when choosing the right steel for your project.

Fabrication and Welding Ease

The shape and size of tubular steel influence how easy it is to fabricate and weld. Round tubes are easier to weld due to their smooth, consistent surface, whereas square and rectangular tubes require more precision to align and weld, especially for larger sections. Additionally, larger sizes may require specialized equipment or more labor-intensive techniques. Considering the specific fabrication and welding requirements is important for cost-effectiveness and efficiency.

Tips for Sourcing the Right Tubular Steel Sizes

When sourcing tubular steel, it’s essential to choose a reliable supplier to ensure high quality, compliance, and cost-efficiency. Here are some tips to guide your decision:

- Choose a Trusted Supplier: Look for suppliers with a proven track record of providing high-quality tubular steel. A reliable supplier will offer certifications that guarantee the materials meet industry standards for strength and durability.

- Ensure Compliance with Standards: Verify that the tubular steel complies with national and international standards to ensure it meets the required specifications.

- Request Detailed Specifications: Be clear about your project’s requirements and request detailed specifications from the supplier to ensure the sizes, wall thicknesses, and finishes match your needs.

- Evaluate Cost and Value: While it may be tempting to go for the cheapest option, consider the overall value. Quality steel may cost more upfront, but it will save money eventually by reducing maintenance and extending the life of your structure.

- Check Availability and Delivery Times: Timely delivery is essential to keep your project on schedule. Ensure that the supplier has sufficient stock and can meet your required delivery times to avoid delays.

- Seek Recommendations and Reviews: Before deciding, look for recommendations from peers or check reviews to gauge the supplier’s reputation. Positive feedback from other customers is a good indicator of reliability.

Understanding the sizes of tubular steel in construction or any fabrication project is important. Accurate sizing ensures the structural integrity, performance, and safety of the finished product. Whether you are working with round, square, or rectangular steel, selecting the appropriate size helps meet load-bearing requirements, improve durability, and ensure ease of fabrication. By considering factors such as load capacity, weight, and welding ease, you can make informed decisions that will benefit your project in the long term.

Build Stronger with He-Max’s Complete Range of Tubular Steel Sizes in the Philippines

Explore He-Max Industrial Corporation’s wide selection of tubular steel sizes for all your construction and fabrication needs. With a complete range of round, square, and rectangular tubular steel, He-Max ensures premium materials and competitive pricing. Our commitment to on-time delivery and expert support makes us a trusted partner for your steel requirements.

Contact us today for a customized quote and expert advice to help you choose the perfect tubular steel for your next project.

For more information or inquiries, feel free to contact us at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial