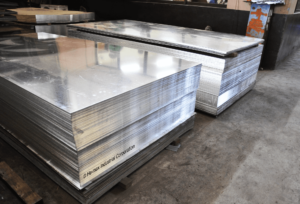

Galvanized sheets are widely used in construction, roofing, and industrial applications due to their durability, corrosion resistance, and cost-effectiveness. These metal sheets, coated with zinc to prevent rusting, are essential in infrastructure projects, manufacturing, and even household applications.

Understanding the factors that influence the price of galvanized sheets is crucial for contractors, hardware stores, and manufacturers. Prices fluctuate due to multiple elements, and knowing these factors helps businesses and individuals make informed purchasing decisions while navigating current galvanized steel prices and optimizing costs.

Key Factors That Affect the Price of Galvanized Sheets

The cost of galvanized sheets in the Philippines is influenced by several factors that contribute to pricing fluctuations. From raw material costs to global market conditions, these elements play a crucial role in determining the final retail price. Understanding these key factors helps buyers anticipate price changes and make informed purchasing decisions. Below, we break down the major factors affecting the cost of galvanized sheets and how they impact procurement strategies:

Raw Material Costs

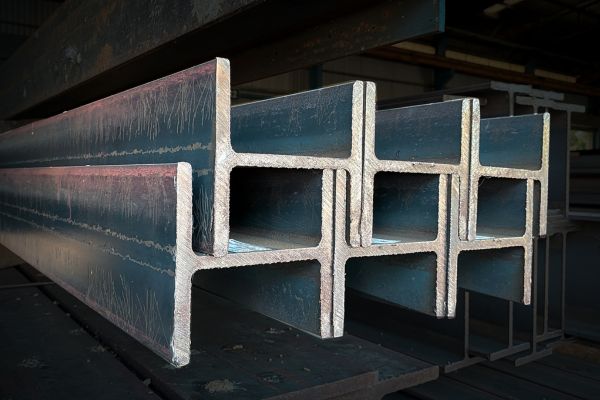

The cost of galvanized sheets is significantly influenced by the prices of raw materials, primarily steel and zinc. Steel serves as the base material, while zinc provides the protective coating that enhances durability and rust resistance.

Global and local market fluctuations play a major role in determining raw material prices. Changes in supply and demand, geopolitical events, and trade policies can all cause price shifts. For example, disruptions in steel production or mining operations for zinc can result in increased costs, which affect the final price of galvanized sheets in the Philippines.

Galvanization Process

The method used in galvanization affects both the quality and the cost of the final product. There are two primary types of galvanizations: hot-dip galvanization and electro-galvanization.

Hot-dip galvanization involves immersing steel sheets in molten zinc, forming a thicker and more durable protective coating. This process offers superior corrosion resistance but tends to be more expensive due to the additional material and energy costs involved.

On the other hand, electro-galvanization is a thinner coating process using an electrical current to apply zinc. While this method is more cost-effective, it may not provide the same level of corrosion protection as hot-dip galvanization. The thickness of the zinc coating also affects pricing; a thicker coating enhances durability but comes at a higher cost.

Market Demand

Demand for galvanized sheets fluctuates based on seasonal and industry-related factors. The construction boom in the Philippines, particularly in urban developments and infrastructure projects, increases demand, pushing prices higher.

Additionally, supply chain disruptions such as shipping delays, raw material shortages, and production halts can impact pricing. Higher demand with limited supply leads to increased costs, making it essential for buyers to plan their purchases strategically.

Transportation Costs

Logistics expenses, including fuel prices, shipping, and handling fees, contribute to the final cost of galvanized sheets. Sheets transported over long distances, particularly imported materials, tend to carry higher costs due to freight charges and customs duties. Additionally, local distribution costs, such as warehousing and last-mile delivery fees, affect pricing. Businesses located near major industrial hubs may enjoy lower transportation expenses, making regional pricing variations another consideration when purchasing.

Currency Exchange Rates

Fluctuations in the Philippine peso against major currencies impact the cost of imported materials, including galvanized sheets. Since many raw materials and finished products are sourced internationally, exchange rate volatility can affect pricing.

When the peso weakens against the US dollar or other foreign currencies, import costs rise, leading to increased product prices. Conversely, a stronger peso may result in lower costs, making it beneficial for buyers to monitor exchange rates when planning bulk purchases.

Size and Thickness of Sheets

The size and thickness of galvanized sheets play a crucial role in determining their price. Thicker sheets require more material and provide greater strength and durability, but they also cost more.

Sheets come in various widths, lengths, and thicknesses, catering to different applications. Contractors and manufacturers must carefully assess their project requirements to select the most cost-effective options without compromising quality and performance.

Tips for Buyers: How to Get the Best Value

Purchasing galvanized sheets can be a significant investment, especially for contractors and businesses that require bulk orders. Finding the best value involves more than just comparing prices—it requires careful assessment of material specifications, supplier reliability, and cost-saving strategies. By understanding the best practices for purchasing galvanized sheets, buyers can make more informed choices and maximize their budget. Below are essential tips to help you get the best deal while ensuring quality and performance.

Choose the right specifications for your project.

Selecting the appropriate sheet thickness is critical for both performance and cost-efficiency. Thicker sheets provide better protection but may not be necessary for all applications. Evaluating structural requirements ensures that buyers do not overpay for unnecessary thickness levels. Consulting with industry professionals can help determine the ideal specifications for different projects.

Purchase in bulk for cost savings.

One of the best ways to save on galvanized sheet costs is to buy in bulk. Many suppliers offer discounts for large orders, reducing the per-unit price. Establishing long-term partnerships with reliable suppliers can also lead to better deals, priority service, and more favorable payment terms. Businesses that require galvanized sheets regularly can benefit from negotiated contracts to secure stable pricing.

Compare local vs. imported options.

Both locally manufactured and imported galvanized sheets have pros and cons. Local suppliers may offer quicker delivery times and lower transportation costs, while imported sheets may provide a wider variety of options. Comparing prices, quality, and lead times between these sources allows buyers to choose the best deal. Keeping an eye on global steel market trends also helps in deciding whether to source locally or internationally.

Making Smart Purchasing Decisions

Understanding the factors that affect the galvanized sheet price in the Philippines is crucial for businesses and individuals looking to optimize costs. Raw material costs, production processes, market demand, transportation expenses, currency exchange rates, and sheet specifications all contribute to price variations.

By evaluating these factors and implementing smart purchasing strategies, buyers can make cost-effective decisions while ensuring high-quality materials for their projects. Keeping an eye on market trends and partnering with reputable galvanized sheet suppliers further enhances purchasing efficiency.

Choose He-Max Industrial for Quality & Competitive Pricing

He-Max Industrial Corporation provides durable and cost-effective galvanized sheets for various applications, ensuring high-quality materials at competitive prices.

Get the best rates and consistent availability from a trusted supplier in the Philippines. Our team offers professional guidance on selecting the right galvanized sheet specifications for your needs. Reach out at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial