H-beams are essential structural components in heavy-duty warehouses and storage facilities because of their strength, stability, and load-bearing capacity. This guide will explain how H-beams enhance structural integrity and efficiency in industrial storage solutions. From construction contractors to warehouse operators, understanding the power of H-beams can help you maximize durability and long-term performance in your storage infrastructure.

Whether you’re searching for an H-beam supplier in the Philippines, evaluating steel H-beam cost, or exploring the differences between stainless steel H-beams, galvanized H-beams, and heavy-duty beams, this guide is tailored to help.

Key Takeaways:

- H-beams are essential for strong, stable, and efficient warehouse structures.

- They offer superior load-bearing capacity, supporting heavy weights and large spans without bending.

- Wide flanges enhance stability and resistance to lateral forces, ideal for tall racking systems.

- Materials include stainless steel (corrosion-resistant), galvanized steel (rust-resistant), and carbon steel (high tensile strength).

- H-beams maximize vertical storage, reduce material costs, and require minimal maintenance.

- Ideal for heavy equipment warehouses, cold storage, and logistics centers due to their durability and adaptability.

- Using H-beams ensures long-term safety, stability, and cost efficiency in warehouse construction.

High Demands for H-Beams

In large-scale construction projects, especially in warehouses and industrial storage facilities, structural reliability is non-negotiable. As modern warehouses grow taller and more complex, the demand for high-capacity frameworks has grown exponentially. This is where H-beams come into play.

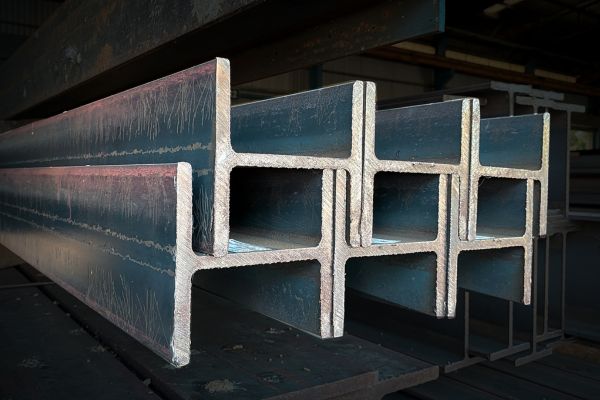

An H-beam, also called a universal beam, is designed with a wide flange and straight edges—offering exceptional support for vertical loads. It serves as the backbone of many warehouse frameworks, racking systems, and mezzanine floors because of its ability to bear heavy weights without warping or bending.

Why H-Beams Matter in Warehouse Construction:

- Enhance stability and safety in tall racking systems.

- Provide long-term durability even under demanding conditions.

- Allow efficient space planning in high-density storage environments.

As warehousing and logistics continue to evolve, H-beams are vital in delivering both strength and cost-efficiency.

Structural Benefits of H-Beams in Warehouses

Superior Load-Bearing Capacity

One of the defining features of H-beams is their outstanding load-bearing performance. Their structural shape allows them to handle:

- Heavier weights

- Higher stress

- Larger spans with no excessive support

This is important for H-beam keeping walls and multi-level warehouse systems, where heavy pallets, industrial equipment, and inventory are stored. In these scenarios, only heavy-duty beams like H-beams can maintain integrity without compromising safety.

Wide Flange Design for Stability

Unlike I-beams, which have narrow flanges, H-beams boast wide flanges that distribute weight more evenly across the surface. This design:

- Minimizes bending and twisting

- Increases lateral stability

- Offers better resistance against horizontal forces like wind or shifting loads

This makes H-beams ideal for earthquake-prone regions or industrial zones that require robust support structures.

Durability & Longevity

H-beams are typically made from carbon steel, stainless steel, or galvanized steel—each offering unique benefits:

- Stainless Steel H-Beams – Excellent corrosion resistance; ideal for humid and coastal environments.

- Galvanized H-Beams – Coated with zinc to prevent rust, suitable for outdoor and industrial use.

- Carbon Steel H-Beams – High tensile strength and durability at a lower cost.

Regardless of the material, H-beams resist wear and tears from stress, impact, moisture, and temperature changes—ensuring a long service life with minimal maintenance.

Maximizing Space & Efficiency with H-Beams

In warehouse design, it’s not just about strength, it’s also about maximizing space and operational efficiency. H-beams play a critical role in optimizing warehouse layouts.

Optimized Vertical Storage

With the rise of vertical warehousing, businesses need to go up—not out. H-beams are perfect for supporting:

- Tall pallet racking systems

- Mezzanine floors for office or storage expansion

- Multi-level conveyor and shelving systems

Their structural integrity ensures that warehouses can safely scale upwards without adding unnecessary columns that eat up valuable floor space.

Flexible Layout & Customization

Every warehouse has unique layout requirements. H-beams offer flexibility to accommodate:

- Custom spacing between columns

- Integration with steel decking, catwalks, and crane rails

- Adaptability for future expansion or reconfiguration

Their standardized sizes and lengths make them easy to fabricate, change, and integrate into both existing and new structures.

Reduced Material Costs & Maintenance

While steel H-beam cost may appear higher upfront, their long-term value becomes clear over time:

- Fewer beams are needed because of their strength

- Less reinforcement or bracing required

- Reduced maintenance because of their durability

In essence, H-beams offer better cost-efficiency than lower-grade beams that require frequent replacement or repair.

Industry-Specific Applications of H-Beams in Storage Facilities

Let’s explore how H-beams serve different warehouse environments across industries.

Heavy Equipment Warehouses

These facilities store bulky and heavy machinery that intensely pressures the floor and structural supports. Heavy-duty beams like H-beams provide the strength and load distribution necessary to:

- Prevent floor deformation

- Support cranes and overhead systems

- Maintain structural stability during equipment movement

Cold Storage & Industrial Racking Systems

Cold storage warehouses must operate under freezing or sub-zero conditions. This environment demands materials that:

- Resist brittleness

- Maintain strength despite temperature changes

- Prevent corrosion from condensation

Galvanized H-beams and stainless-steel H-beams are ideal choices, ensuring reliability and safety in extreme conditions.

Logistics & Distribution Centers

With constant movement, high stacking, and automated systems, logistics hubs require a structural backbone that:

- Supports heavy duty beams and dynamic loads

- Allows for rapid layout changes

- Facilitates safe workflows

H-beams make it possible to create efficient and scalable layouts for inventory processing, sorting, and shipping operations.

Conclusion

H-beams are the unsung heroes of modern warehouses and industrial storage design. Their strength, stability, and long-term performance make them the go-to structural component for building safer and more efficient facilities.

To recap, H-beams offer:

- Superior load-bearing capacity for vertical and horizontal stresses

- Stability in wide flange designs that improve weight distribution

- Durability that stands the test of time and environmental exposure

- Flexibility to adapt to your warehouse’s unique layout and needs

- Cost-efficiency by reducing material requirements and maintenance costs

Whether you’re designing a high-rise cold storage facility or building a heavy-duty equipment warehouse, using high-quality H-beams is essential.

Build a Stronger Warehouse with HE-MAX Industrial’s High-Quality H-Beams

Looking for top-quality H-beams for your construction or industrial projects? HE-MAX Industrial Corporation offers a wide selection of premium-grade H-beams designed to meet diverse structural requirements. Trusted by contractors and builders nationwide, we ensure quality, durability, and timely delivery for every order.

Our H-Beam selection includes:

- Stainless Steel H-Beams

- Galvanized H-Beams

- Heavy-Duty Carbon Steel H-Beams

- H-Beams for Retaining Walls, Racks, and Structural Frames

Get the right support for your projects with HE-MAX. Call us now at 0917-1158387 / 0925-8092196 to discuss your needs or visit our Contact Us page for a quote or consultation. Stay updated with our latest offers by following us on Facebook. Explore our wide range of products and services to find the perfect solution for your project. Choose HE-MAX for dependable H-beam solutions.