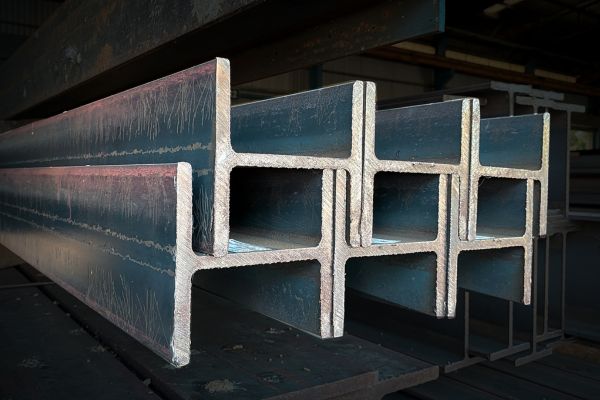

Structural steel elements with broad, flat flanges and a sturdy vertical web, known as wide flange beams, can support heavy loads. They are essential for supporting walls, floors, and roofs in various construction projects, from industrial structures to residential buildings, due to their exceptional strength, stability, and versatility. For builders considering these beams, understanding the wide flange price in the Philippines is vital for budgeting and ensuring cost-efficient yet reliable solutions.

Choosing the right wide flange beam depends on factors like load-bearing requirements, span length, and structural design. The size and weight of the beam should match the project’s needs and construction limits, while material grade and strength ensure safety and reliability. Intended use and environmental conditions also affect durability and compatibility. By considering these elements, builders can select the right beams for construction that deliver optimal support, stability, and efficiency for their specific project.

Understanding Project Requirements

Understanding project requirements is crucial when selecting structural steel beams, such as wide flange beams, to ensure the correct load capacity, size, and material strength, providing the necessary support, stability, and safety for the structure.

A. Load-Bearing Needs. It is crucial to evaluate the load-bearing requirements based on the structural design when selecting the appropriate broad flange beam. Consider the entire weight that the beam is required to sustain, including both dead and living loads, such as the weight of the beam itself and people and equipment. By accurately estimating these stresses, structural failure can be avoided, and the beam can offer sufficient support and stability. For safety and performance to be maintained, choosing a beam with the proper strength and load capacity is essential.

B. Environmental Conditions. Choosing the right wide flange beam is greatly influenced by environmental factors. Conditions like humidity, corrosive substances, and extreme weather can affect the beam’s durability. In harsh environments, selecting materials with protective coatings or better corrosion resistance is essential. Understanding these factors ensures the beam maintains its strength over time, reduces maintenance needs, and enhances safety, especially in outdoor or industrial applications exposed to tough conditions.

C. Project Scale and Design Specifications. Choosing the right wide flange beam means matching its size to the project’s structural needs and architectural design. Larger, stronger beams are often required for bigger projects like commercial buildings or bridges, which need to support heavier loads and longer spans. For smaller or residential buildings, more compact beams may be enough. By aligning the beam’s size and strength with the design’s specific load and span requirements, you ensure the stability and integrity of the structure.

Types of Wide Flange Beams

Wide flange beams are among the various construction beam types, each specifically designed to meet unique structural needs.

- Standard Wide Flange Beams. This is the most common type that provides reliable support for a wide range of typical construction projects. They’re ideal for buildings, bridges, and other structures that have moderate load-bearing and span requirements. These beams offer cost-effective, flexible support for standard applications.

- Heavy Wide Flange Beams. For high-stress, load-heavy projects like large bridges, high-rise buildings, or massive industrial structures, Heavy Wide Flange Beams are the go-to choice. These beams are built for strength and durability, making them perfect for situations where structural integrity is critical. Their ability to handle heavier loads and longer spans ensures stability in demanding applications.

- Specialized Beams. Specialized beams are designed for custom applications with unique needs. These can include beams treated to resist heat, corrosion, or other environmental factors, or made from specific material grades, such as high-strength steel. Choosing the right material grade ensures the beam’s durability and performance in tough environments. For example, higher-grade steel can improve wear resistance and load-bearing capacity, making it ideal for projects that demand long-term durability or need to withstand harsh conditions. Selecting the right type and grade of beam ensures both safety and optimal performance.

Selecting the appropriate wide flange beam grade is essential for optimum performance and longevity. High-grade materials, such as high-strength steel, are perfect for demanding applications because they provide better resistance to environmental conditions, corrosion, and wear. Industrial steel beams made from the right material grade will function dependably over time, enhancing load-bearing capacity, durability, and structural integrity. The beam will meet both short-term and long-term performance criteria if the right grade is chosen for the particular project conditions.

Sizing and Dimension Considerations

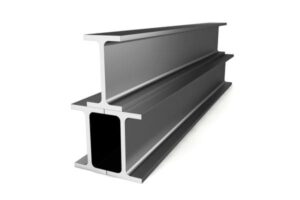

In order to ensure the best possible support, stability, and performance for structural integrity and safety, sizing, and dimension considerations center on choosing the appropriate beam depth, flange width, and weight in accordance with project criteria.

Beam Depth, Flange Width, and Weight. When selecting a wide flange beam, wide flange beam dimensions such as beam depth, flange width, and weight are key factors to consider. Beam depth determines the load-bearing capacity and resistance to bending, making it crucial for handling heavy loads or long spans. Flange width impacts the beam’s stability and overall strength, ensuring it meets structural demands. Weight should align with the project’s load and design requirements to avoid overloading or inefficiencies. By choosing these specifications carefully to match project needs, you ensure the beam provides reliable support, stability, and structural integrity for safe and efficient construction.

Avoiding Over- and Under-Specification. Under-specifying a wide flange beam can compromise structural integrity, while over-specifying can drive up costs unnecessarily. To find the right balance, carefully evaluate load requirements, span length, and environmental conditions. Choose a beam that meets these needs without exceeding them. Consulting structural engineers and using design software can help identify the most cost-effective and reliable option. Focus on material grades and dimensions that ensure durability and performance without overbuilding, maintaining both the safety of the structure and the project’s financial feasibility.

Find the Perfect Wide Flange Beam with He-Max Industrial

A wide selection of premium beams made to satisfy various building requirements is available from He-Max Industrial Corporation. He-Max guarantees strength, durability, and dependability with anything from heavy-duty solutions for load-intensive projects to ordinary wide flange beams for general support. Specialized beams made for particular uses are also included in their inventory, along with a range of material grades and treatments to improve longevity and performance. He-Max beams give builders reliable options for building residential, commercial, and industrial structures in a safe, effective, and sustainable manner.

He-Max Industrial Corporation specializes in helping clients choose the right beams and materials, ensuring every construction project achieves optimal performance, cost-effectiveness, and lasting durability.

He-Max Industrial Corporation provides expert advice and dependable product options to meet your project’s specific needs. Whether you need standard or custom beams, their team offers tailored guidance. Contact He-Max for high-quality solutions that ensure safety, efficiency, and long-lasting performance for all your construction projects.

For more information or inquiries, feel free to contact us at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial