The Philippine construction industry has embraced innovative methods like steel fabrication, revolutionizing how projects are built. Steel fabrication in the Philippines encompasses skyscrapers and warehouses to garages and residential properties. That’s why structural steel plays a crucial role in modern construction.

Steel is an alloy of iron and other materials, and its versatility allows for a wide range of steel types, each with unique benefits and drawbacks.

The steel fabrication process creates versatile components tailored for diverse applications, making it the top choice for builders, engineers, and contractors. Its popularity stems from its quality, reliability, flexibility, cost-effectiveness, and sustainability, making it indispensable across industries.

This steel fabrication guide will discuss the basic methods of steel fabrication to help contractors, sub-contractors, and other construction hardware firms look for reliable and trusted industrial steel fabricators for their projects and businesses.

What is Steel Fabrication?

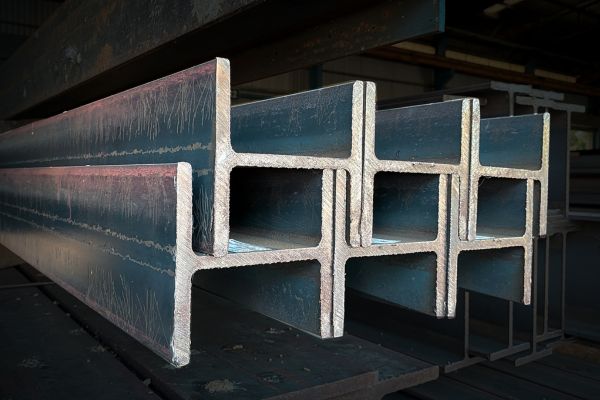

Steel fabrication entails manufacturing components like beams, columns, and rafters in a controlled factory setting based on design specifications. Adhering to strict procedures ensures components meet quality standards, streamlining steel frame installation during construction.

Steel fabrication basics involve cutting, bending, rolling, fitting, fastening, and cleaning steel to create predefined structures like frames, platforms, and ladders. This process assembles and joins steelwork components to form complete structural steel frames, either in a shop or on-site.

Core Processes in Steel Fabrication

Steel fabrication is a precise and skilled process requiring a structured approach. Machinists tasked with steel fabrication begin by assessing the raw material, which may come as flat plates, reshaped channels, pipes, or other forms.

Here’s a general overview of the key steps involved in the steel fabrication process:

A. Cutting and Machining

Shaping steel through various techniques such as sawing, drilling, turning, and grinding. Specialized methods include:

- Shearing and Cropping: Cutting steel into specific lengths and widths.

- Flame Cutting: Using high-pressure oxygen flames for efficient, precise cuts.

- Plasma Fusion Cutting: An electric arc heats the gas to achieve high-precision cuts.

- Cold Sawing: Cuts steel to precise lengths with computer-aided accuracy.

B. Punching and Drilling

Creating holes in steel components using numerically controlled machines is crucial for assembling components with bolts and fasteners.

C. Straightening, Bending, and Rolling

To correct distortions from transport or production, roller bending is used to straighten or shape steel to meet structural requirements.

D. Fastening

Joining structural components through:

- Bolting: Connecting parts securely with bolts and nuts.

- Riveting: Providing permanent, strong fasteners.

- Welding: Fusing parts using heat and pressure for a solid bond.

E. Quality Control

Detailed inspections ensure that fabricated steel adheres to client specifications, with comprehensive reports verifying compliance with industry standards.

F. Surface Treatment

Enhancing steel’s durability and appearance through:

- Blasting and Painting: Smoothening surfaces and applying protective coatings.

- Galvanizing: Coating steel with zinc to prevent rust and corrosion.

Types of Steel Plates in Fabrication

Steel plates are among the most versatile materials in construction, valued for their durability, adaptability, and range of applications. These plates come in various types, each with unique properties tailored to specific construction needs.

For the best results, rely on an experienced engineering company with skilled professionals and advanced machinery. Here are some common types of plates used:

Checkered Plates

Characterized by raised angular patterns, checkered plates enhance surface grip, reducing slips and skids. Commonly used for walkways, industrial stairs, parking floors, and elevator flooring, they offer safety and durability. Checkered plates are also easy to maintain, as their texture resists dirt, oils, and liquids.

Galvanized Plates

Galvanized steel plates are coated with molten zinc, offering exceptional corrosion resistance and durability. These plates withstand wear and tear, making them ideal for roofing, sheds, water heaters, and automotive components. Their anti-corrosive treatment ensures a long lifespan, even in varying temperatures.

Mild Steel Plates

Highly versatile and easy to use, mild steel plates are the go-to choice for construction projects. As a type of carbon steel, they are easily welded, bent, and shaped, making them suitable for building infrastructures like warehouses, bridges, and terminals. They’re also utilized in shipping and offshore equipment fabrication.

B.I. and G.I. Plates

Black Iron (B.I.) and Galvanized Iron (G.I.) plates are widely used in construction. G.I. plates feature a zinc coating for corrosion resistance, while B.I. plates are made with copper and aluminum. Both undergo galvanization processes, enhancing their strength and resistance to environmental factors.

Steel plates are essential in constructing bridges, railways, warehouses, and buildings. Selecting the right specifications is vital to meet the unique demands of each project.

Major Applications of Steel Fabrication

Steel fabrication plays a crucial role in construction and is commonly used in various applications including construction, automotive, industrial machinery, and even consumer products.

High-rise buildings benefit from its strength, lightweight properties, and expedited construction timelines.

Industrial and warehouse buildings leverage steel for creating expansive spaces at a relatively low cost, making it an ideal choice for functionality and efficiency.

In residential construction, light gauge steel is frequently employed for its versatility and durability.

Cars and trucks rely on fabricated steel parts for safety and performance, while heavy equipment and tools are powered by fabricated steel components. Everyday items like appliances and furniture often feature steel fabrication.

Your Trusted Partner for Steel Fabrication in the Philippines– He-Max Industrial Corporation

He-Max Industrial Corporation specializes in delivering precision-engineered steel solutions. Whether you’re constructing the next architectural marvel or need custom parts for your machinery, we are committed to providing superior quality and unmatched expertise.

He-Max Industrial strives to be the industry benchmark for exceptional service and quality steel supply.

We are committed to delivering top-grade steel that adds value to our client’s businesses while expanding our market through excellent products and competitive pricing.

Our focus is on fostering long-term partnerships founded on reliability, integrity, and mutual respect. Our portfolio spans across various fields—from commercial, and industrial to agricultural.

Want to know more about steel fabrication in the Philippines and the steel fabrication process? Check our website to learn more about our steel products and services. You can also find us on Facebook.

For more information or inquiries, feel free to contact us at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

- Email: hemaxsales@gmail.com

Follow us on social media for updates and more industry insights:

Facebook: https://www.facebook.com/hemaxindustrial