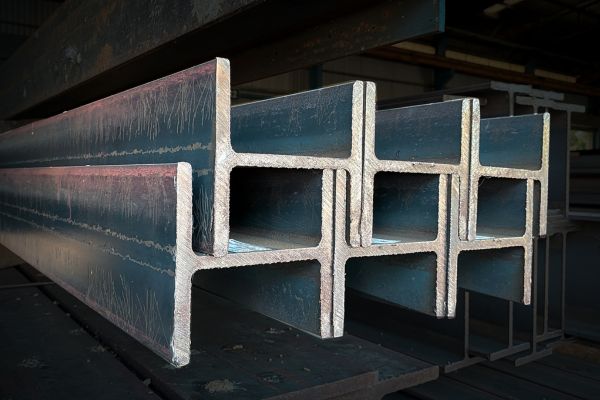

H-beams are vital for maintaining structural integrity and providing strong support for load-bearing components in buildings and bridges. With their wide flanges and vertical web, they efficiently distribute weight, making them key for high-stress applications and large construction projects that require durability and safety.

As structures age, timely sheet piling and structural beam replacement are key to avoiding structural issues. Over time, wear and environmental factors can weaken materials, risking safety and stability. Replacing them early ensures long-lasting performance, reduces costly repairs, and maintains the structure’s integrity.

To keep your building or project safe and durable, it’s important to recognize signs that your H-beams may need replacing, like structural damage, corrosion, or a loss of integrity, especially as part of ongoing structure maintenance.

Sign 1: Visible Corrosion and Rust

Rust can significantly weaken H-beams by corroding the steel structure. When exposed to moisture and oxygen, rust forms on the beam’s surface and slowly erodes the metal. Over time, this corrosion reduces the beam’s cross-sectional area, diminishing its load-bearing capacity. Cracks from rust can compromise the beam’s integrity, potentially leading to failure in critical areas. Additionally, rust can cause pits or uneven surfaces, further reducing the beam’s strength. Regular inspections and timely maintenance, such as rust removal and protective coatings, are crucial to ensuring the long-term strength and durability of H-beams.

To check for corrosion in hard-to-reach areas, use tools like borescopes or cameras with flexible probes. Perform regular visual inspections and listen for unusual sounds. For deeper corrosion, consider ultrasonic or magnetic particle testing to assess the beam’s integrity without direct access, especially during routine construction maintenance.

Sign 2: Warping or Bending

H-beams can bend over time due to excessive load, material fatigue, or poor structural design. Continuous stress beyond the beam’s capacity can lead to deformation, while repeated loading cycles weaken the material. Corrosion, thermal expansion, or uneven pressure from installation or foundation issues can also cause bending. Regular inspections and proper load distribution are essential to prevent bending and maintain the long-term stability of H-beams.

Even slight warping in H-beams can affect their ability to distribute stress evenly, which can compromise structural integrity. Over time, this distortion can cause uneven stress points, leading to further deformation. As the beam bends or twists more, its load-bearing capacity decreases, increasing the risk of failure in key areas. It’s important to address even minor warping immediately to maintain the beam’s strength, stability, and overall safety of the structure.

Sign 3: Cracks or Fractures

Cracks in H-beams often point to issues like corrosion, overloading, or material fatigue. These cracks can signal that the beam is losing its load-bearing capacity, putting the structure’s safety at risk. They typically form stress points or weak areas, such as bends or rusted spots. Detecting cracks early is key to preventing further damage. Prompt inspection and building structure repair are necessary to maintain the beam’s integrity and avoid potential structural failure in critical parts of the building or infrastructure.

Temperature changes cause H-beams to expand and contract, creating stress that can weaken the material over time. This tension, especially at weak points or areas of wear, can lead to cracks when combined with external loads. Frequent temperature fluctuations, particularly in extreme conditions, speed up this process. Over time, the ongoing expansion, contraction, and additional stress can compromise the beam’s structural integrity.

Sign 4: Loose Connections or Welds

For H-beams to stay stable and ensure the structure functions properly, secure connections are a must. Weak or poorly secured joints can create stress points, leading to misalignment, shifting, or even failure under load. When beams are connected properly, the forces are spread evenly, preventing concentrated strain or damage. It’s crucial to ensure strong, well-made connections during installation and maintenance to avoid structural issues and maintain long-term safety and stability.

Warning signs of failing welds or bolts in H-beams include visible cracks, discoloration, or corrosion around the welds and fasteners. If bolts loosen or show signs of wear, such as rust or deformation, this suggests weakening connections. Unusual noises like popping or cracking could also signal stress on the welds or bolts. Additionally, misalignment or shifting beams may indicate a failed connection. Regular inspections and early detection of these issues are crucial to prevent further damage and maintain the structure’s safety and stability.

Sign 5: Increased Structural Load Requirements

The stability and safety of the structure are jeopardized when H-beams are unable to support the revised load requirements. When loads from equipment, new floors, or shifting uses exceed the beams’ initial capability, deformation or failure may result. To ascertain whether the beams satisfy modern criteria, routine inspections are necessary. If not, the integrity of the structure may need to be preserved by redesign, replacement, or reinforcement. It is crucial to manage load changes as they occur because delaying treatment can result in expensive repairs, safety risks, and even collapse.

Reevaluating the load capacity of older structures, including through steel beam inspection, is key to ensuring their ongoing safety and functionality. Over time, wear and environmental factors can weaken materials, reducing their ability to handle modern loads. Changes like additional floors, increased traffic, or shifts in building use can also strain the original design. Regular assessments help ensure the structure meets current load-bearing standards and identify potential issues. By reassessing load capacity, necessary reinforcements or upgrades can be made, preventing costly failures, and ensuring long-term stability, safety, and compliance with modern regulations.

Ensure Your Structure’s Safety with Quality H-Beams from He-Max Industrial Corporation

For a variety of building applications, He-Max Industrial Corporation, a trusted H-beam supplier in the Philippines, provides a large selection of dependable, premium H-beams. He-Max offers solutions that guarantee structural integrity and long-lasting performance for all kinds of projects with an emphasis on strength, durability, and accuracy.

He-Max Industrial Corporation offers a wide range of long-lasting H-beams that are perfect for replacements as well as other construction projects. Their superior beams are made to satisfy structural requirements and guarantee enduring performance. He-Max assists customers in choosing the best materials for their requirements with professional advice and first-rate assistance, guaranteeing seamless and effective replacement projects. He-Max guarantees that every beam satisfies the highest standards of durability and safety, whether it is being used to upgrade or reinforce structures.

Consult He-Max Industrial Corporation for professional advice, estimates, and customized solutions. Our team is prepared to help you choose the best materials for your project, guaranteeing long-term performance, quality, and durability. Get in touch with us right now for individualized assistance and dependable, superior goods.

For more information or inquiries, feel free to contact us at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial