The Philippines is a key automotive hub in Southeast Asia, with the industry split mainly into two parts: manufacturing and vehicle assembly.

In the automotive industry, the cost of raw materials is critical in determining profitability, pricing, and overall competitiveness.

Steel prices, particularly for tubular steel in the Philippines, fluctuate due to raw material pricing, supply chain difficulties, and market demand. Staying current helps businesses remain competitive and successful.

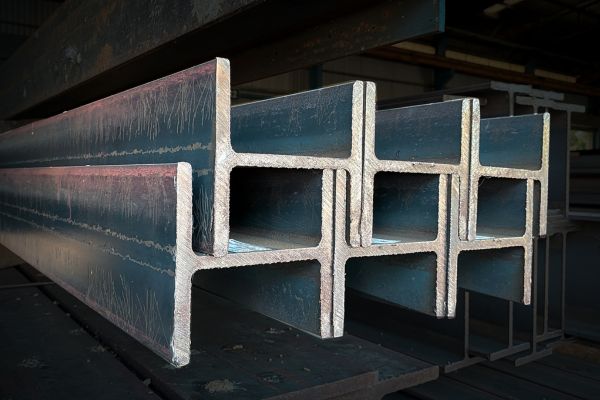

Steel in the Automotive Industry

Steel remains the backbone of automotive innovation, giving strength, flexibility, and resilience to a variety of components.

Tubular steel is used extensively in the automotive sector, with applications including tubular steel chassis, automotive steel sheet and frames, exhaust systems, roll cages, and racks. Its lightweight yet sturdy design makes it vital for improving fuel efficiency and overall vehicle performance.

This material is not just a standard in original equipment manufacturer (OEM) production, but it is also extensively employed in local auto customization, allowing for both functional and cosmetic upgrades

Steel Types Steering the Auto Industry

- Stainless Steel – Sleek, sturdy, and corrosion-resistant, stainless steel is ideal for exhaust systems and trimmings, providing both functionality and style due to its rust-resistant features.

- High-Carbon Steel – The group’s muscle, high-carbon steel, is robust and appropriate for high-stress components such as gears and shafts. Despite being difficult to weld, it is extremely durable.

- Low-Carbon Steel – Low-carbon steel is a popular choice for body panels and structural parts due to its flexibility and ease of welding. It also provides strength and malleability for shape and fabrication.

- Advanced High-Strength Steel – Lightweight yet extremely sturdy, this material improves fuel efficiency and safety, allowing manufacturers to fulfill stricter standards without sacrificing performance.

- Galvanized steel – Galvanized steel’s zinc coating provides maximum protection against rust, making it the best choice for parts exposed to extreme weather conditions

Factors Affecting Tubular Steel Prices in the Philippines

Understanding what drives tubular steel prices in the Philippines is the first step in grasping its impact. Several global and local factors are at play:

- Global Steel Market Trends – International demand-supply imbalances, fluctuations in raw material pricing (e.g., iron ore and coal), and shifts in production by key exporters (e.g., China and India) can cause rippling effects across regional markets, affecting automotive steel prices.

- Import Tariffs and Currency Rates – The Philippines primarily relies on steel imports. Tariffs, trade policies, and peso-dollar exchange rates can have a substantial impact on landed costs, particularly for steel used in the car industry.

- Shipping and Logistics – Rising freight prices and port congestion can increase import expenses, especially during global disruptions.

- Local Capacity Limitations – Due to inadequate steel manufacturing facilities, the country relies heavily on imported steel, leaving it vulnerable to external shocks.

Peaks in construction and industrial activity can lead to restricted supply and higher pricing, particularly during infrastructure booms or pre-election periods with increased public works spending.

How Price Fluctuations Affect the Auto Industry

Manufacturing Costs

Local car producers, particularly those making utility vehicles, delivery vans, and jeepneys, may see immediate cost hikes as steel prices rise.

The tubular steel chassis is the foundation of these vehicles’ frames and body components. Even slight price increases might affect profitability on fleet purchases and large production batches, causing manufacturers to reconsider pricing or sourcing methods

Aftermarket Fabrication and Modification

Tubular steel is the most popular aftermarket material for making roll bars, bull bars, roof racks, bumpers, and other bespoke components.

Rising steel costs can be particularly unpleasant for smaller workshops and fabricators who specialize in roll cage fabrication in the Philippines.

With smaller budgets and less purchasing power, these enterprises frequently absorb cost increases, reducing already slim profit margins or risking customer backlash with increased prices.

Vehicle Pricing and Affordability

Ultimately, the end consumer feels the pressure. As manufacturers and mod shops pass on material cost increases, vehicle prices edge upward. This could dampen consumer demand, particularly in a price-sensitive market like the Philippines.

Higher vehicle prices can also affect the competitiveness of locally assembled units compared to imported ones—especially when price changes involve automotive steel sheet and other high-cost components.

Strategies for Managing Tubular Steel Price Volatility

Steel price volatility refers to frequent and significant price swings driven by global market factors.

Changes in global demand brought about by industrial and economic activity, supply chain interruptions, and geopolitical events like trade policy and political unrest are some of the major factors.

Despite challenges in automotive steel prices, there are ways for businesses to adapt

- Secure long-term contracts – Setting prices through long-term contracts with dependable suppliers helps protect against market fluctuations, particularly when it comes to steel used for the automobile sector. Make sure you secure fixed rates or capped pricing formulas and include clauses for market shifts or volume changes.

- Diversify your sources – Relying on multiple suppliers helps cushion the impact of price swings and supply chain disruptions by ensuring you have backup options. That’s why it’s always best to work with suppliers across different regions to avoid regional risks. Consider different steel grades or materials that offer better pricing or stability.

- Lean inventory and just-in-time fabrication – Efficiency and cost management can be enhanced by reducing the expenses associated with keeping inventory on hand and coordinating material deliveries with production schedules. Smarter forecasting and inventory control lead to better buying decisions and less exposure to steel price swings.

- Employ multi-purpose profiles – Using a small number of tubular sizes and shapes for a variety of applications can simplify procurement and cut down on waste.

Steel the Deal with He-Max Industrial Corporation

Keep your automotive projects in high gear with He-Max Industrial Corporation—your trusted source for premium tubular steel.

Whether you’re fabricating fleet vehicles or crafting one-of-a-kind custom builds, our high-quality steel delivers the strength and precision your work demands.

As a trusted steel supplier in the Philippines, He-Max Industrial is committed to delivering not only top-quality products but also exceptional customer support every step of the way.”

Our premium materials are engineered to meet the highest industry standards while keeping your projects efficient and cost-effective.

Visit our website to learn more about our steel products and services. You can also check our Facebook page to learn the latest insights about our promos. You can also drop by our inbox and send us an email at hemaxsales@gmail.com.

Get in touch with us today for inquiries and quotations on tubular steel prices in the Philippines.

Trunkline: (632) 8275-3888

Customer service hotline: 0917-1158387

Email: hemaxsales@gmail.com