According to the Board of Investments, the Philippines’ steel consumption is projected to hit 20 million tons by 2030—a reflection of the nation’s fast-paced urbanization and infrastructure expansion.

In industries like construction, manufacturing, and engineering, precision is non-negotiable. One underrated yet powerful strategy to elevate your project’s efficiency and results is partnering with a steel supplier that also provides in-house fabrication services.

Let’s explore how working with a reliable steel supplier in the Philippines can help you streamline your supply chain—saving time, reducing costs, and ensuring unmatched quality.

Steel Fabrication 101

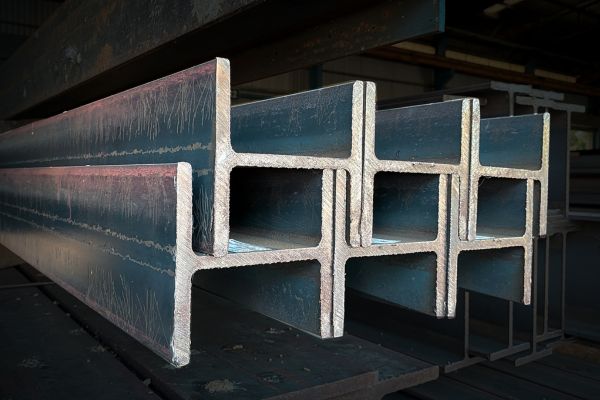

Steel is a top-choice material in the construction industry. Whether it’s the skeletal frame of a building or the metal racks for equipment, steel plays a foundational role.

Steel fabrication involves converting raw metal into durable, functional components through cutting, bending, and assembling. This process is where raw material meets skilled engineering to create everything from support beams to custom sheet metal.

Industrial facilities heavily depend on fabrication to bring concepts to life. By choosing a supplier who is also a structural steel fabricator, you gain the advantage of a simplified process that shortens timelines, improves quality control, and ensures better coordination from design to production.

The Benefits of Consolidated Steel Construction Fabrication

Faster Turnaround Time for Your Projects

Pressed for time? With in-house fabrication, you bypass the need for third-party providers, cutting down delays from material transport or queuing with external fabricators.

Steel is processed and dispatched from a single source, while having a unified team manage everything ensures a smoother, more efficient workflow.

Cost Savings from Consolidated Services

Fewer vendors mean fewer costs. Here’s how partnering with a full-service provider helps:

- Reduced transport and logistics expenses

- Lower labor and handling costs

- Easier administrative coordination

Suppliers offering end-to-end services can also provide bundled pricing. With better material control, there’s less waste, giving you bigger savings over time.

Consistent Quality and Precision

When fabrication and sourcing are handled by the same structural steel supplier, product compatibility and overall precision improve significantly.

This attention to detail contributes not just to your project’s appearance but also to its structural integrity and performance.

With the same team overseeing the entire fabrication process, you’re assured of consistently high standards.

Better Communication and Project Coordination

Having a single team manage both sourcing and fabrication simplifies communication. Fewer handovers mean fewer opportunities for errors or delays.

It’s also easier to adjust or accommodate customizations, as everyone involved works from the same specifications and updates.

Access to Technical Expertise and Engineering Support

Suppliers with in-house fabrication services often employ skilled fabricators and engineers who bring years of experience to the table.

This technical expertise can be invaluable when it comes to design and feasibility discussions, particularly for complex or custom builds such as steel frame fabrication.

If you encounter any challenges during the project, having direct access to engineering support can help resolve issues quickly and effectively.

Scalability for Large or Ongoing Projects

In-house fabrication services offer scalability that third-party fabricators simply cannot match. If your project is ongoing or involves large volumes, long-term partnerships with a single provider ensure that your orders are scaled up seamlessly.

Should you need to repeat or scale up your order, you are assured that consistency is maintained across multiple batches.

Environmental and Compliance Advantages

In-house operations offer greater traceability and help ensure that all materials meet industry standards and local regulations. With better control over processes, many suppliers optimize material use.

For example, an efficient cutting process of custom sheet metals can reduce scrap, which not only helps reduce waste but also supports environmentally responsible practices.

Real-World Applications: Who Benefits the Most?

- Contractors needing custom steel beams or trusses

A single provider can fabricate steel beams or trusses to meet your exact specifications, ensuring they fit perfectly into your construction plans.

- Fabricators requiring raw steel and shaping in one go

If you’re a supplier that offers steel construction fabrication, having access to raw materials and shaping services from a single provider speeds up your workflow and reduces dependency on multiple vendors.

- Manufacturers seeking ready-to-assemble components

For manufacturers, the ability to source and receive prefabricated, ready-to-assemble components streamlines production and cuts down on lead time.

Simply put, when a steel supplier handles both the material sourcing and fabrication in-house, it creates a more cohesive, efficient, and cost-effective process. So why just buy steel when you can get it fabricated too?

Let’s Build Something Greater with He-Max Industrial Corporation

At He-Max Industrial Corporation, we don’t just supply steel—we deliver precision-engineered solutions that build the future. And that includes a wide array of steel fabrication services.

As a proudly Filipino-owned steel supplier in the Philippines, He-Max Industrial is setting the standard for excellence in steel fabrication at a reasonable cost. We aim to be the industry’s benchmark for quality and service, trusted by businesses across commercial, industrial, and agricultural sectors.

Our mission is simple:

- Supply top-grade steel products that enhance your operations

- Offer competitive pricing without compromising quality

- Build long-term partnerships based on trust, integrity, and mutual success

Curious about the steel fabrication process or looking for a reliable structural steel supplier? Visit our website to learn more about how He-Max Industrial can support your projects, from concept to completion.

Explore our full range of steel solutions and services and get the latest updates and promos by following us on Facebook.

Contact us today and let’s discuss your steel needs for your projects:

Trunkline: (632) 8275-3888

Customer service hotline: 0917-1158387

Email: hemaxsales@gmail.com