From a basic structural component, tubular steel has evolved into a cornerstone of contemporary architecture. First introduced in the 19th century for industrial use, its robustness and sleek appearance quickly made it highly popular. Today, strong metal tubing like tubular steel is a top choice for modern designs, meeting the demand for materials that are both strong and lightweight.

Tubular steel provides unparalleled cost-effectiveness, sustainability, and versatility for 2025 projects, making it perfect for creative construction. Find the best tubular steel price in the Philippines to stay competitive.

Key Benefits of Using Tubular Steel in Architecture

Tubular steel is a standout choice in modern architecture, thanks to its exceptional strength, versatility, and efficiency, offering key structural steel benefits. Its unique qualities make it ideal for creating innovative designs, constructing sustainable structures, and managing costs in large-scale projects. Discover how this extraordinary material helps bring today’s boldest architectural visions to life.

- Strength and durability for sustainable structures. Tubular steel’s exceptional strength and durability make it a key material for eco-friendly construction. Its resilience against heavy loads and environmental wear ensures lasting performance, reducing maintenance and waste. This reliability not only supports sustainable building practices but also meets the demands of modern architectural designs.

- Design versatility for innovative architectural aesthetics. Tubular steel’s versatility gives architects the freedom to design bold, inventive structures. Its sleek and flexible form allows for unique shapes and open spaces, seamlessly blending strength with visual appeal. This adaptability makes it ideal for pushing the limits of modern design while ensuring both functionality and structural integrity.

- Cost-effectiveness and efficiency in large-scale projects. For large-scale applications, tubular steel is an affordable option because it uses less material and has great strength. Because it is lightweight, installation and transportation are made easier, saving money on time and labor. It is a wise investment for fulfilling financial and schedule requirements in ambitious architectural undertakings because of its effectiveness and longevity.

Tubular Steel Meets Building Standards

Because tubular steel complies with strict safety and environmental regulations, it meets modern building standards. As a key example of structural metal products, its strength and resistance to environmental factors ensure safety in load-bearing applications and maintain structural integrity. Tubular steel’s durability minimizes the need for frequent repairs and maintenance, supporting sustainable design. Additionally, its recyclability aligns with green construction practices, promoting environmentally friendly building methods. With its safety, long-term performance, and environmental responsibility, tubular steel remains a reliable choice for meeting the evolving demands of modern architectural and construction standards.

Tubular steel enhances construction by easily integrating with other modern materials like wood, concrete, and glass, enabling creative designs that combine strength and style. Its lightweight nature makes it easy to pair with heavier materials, offering structural support without compromising space or design. Its durability ensures long-term performance, meeting safety and functionality standards. This versatility makes tubular steel the go-to choice for creating innovative, contemporary structures that adhere to modern building codes.

Comparison Between Tubular Steel and Other Structural Materials

| Pros of Tubular Steel | Cons of Tubular Steel |

| Strength and Durability: Tubular steel is highly durable, providing long-lasting performance even in harsh environments and under heavy loads. | Cost: Tubular steel tends to have a higher initial cost compared to concrete or wood.

|

| Lightweight: Its lighter weight compared to concrete makes it easier and more cost-effective to transport and install. | Corrosion Risk: Without proper treatment, tubular steel can be vulnerable to corrosion.

|

| Design Flexibility: Tubular steel offers great design potential, allowing for open spaces and sleek, modern architectural forms. | Insulation: Tubular steel lacks the natural insulating properties of wood.

|

| Sustainability: It’s recyclable, supporting eco-friendly construction practices. | Aesthetic Limitations: Tubular steel might not always suit traditional or classic architectural designs. |

| Compatibility: Tubular steel works seamlessly with various materials like concrete, glass, and wood, making it versatile for different architectural styles. |

Comparing to Concrete

- Strength: While concrete offers excellent compressive strength, tubular steel is more versatile as it can handle both compressive and tensile forces.

- Weight: Concrete is much heavier, often requiring stronger support structures, whereas tubular steel is significantly lighter, reducing labor and transportation costs.

- Environmental Impact: Producing concrete is more energy-intensive, while tubular steel is often a more sustainable option, especially when recycled.

Comparing to Wood

- Durability: Tubular steel is far more durable than wood, which can weaken over time due to fire, moisture, or pests.

- Cost: Wood is more affordable and readily available, but it doesn’t match tubular steel in strength or longevity.

- Sustainability: Wood is renewable and biodegradable, but irresponsible sourcing can lead to deforestation. Tubular steel, on the other hand, is highly recyclable, supporting sustainable construction practices.

Selecting the Right Tubular Steel for Your Project

Understanding your project’s needs is the first step in choosing the right tubular steel. For steel building construction, opt for higher-grade steel with greater tensile strength to ensure reliable structural support, while lower-grade options are suitable for decorative purposes. Consider load-bearing requirements and design goals when selecting the size and thickness to align with architectural needs.

Maintenance is key to extending the steel’s lifespan. Opt for steel with protective coatings to prevent corrosion, especially in coastal or humid environments. Regular inspections can help catch wear early, allowing for timely repairs. By carefully selecting and maintaining your tubular steel, you’ll ensure long-term durability and performance for your project.

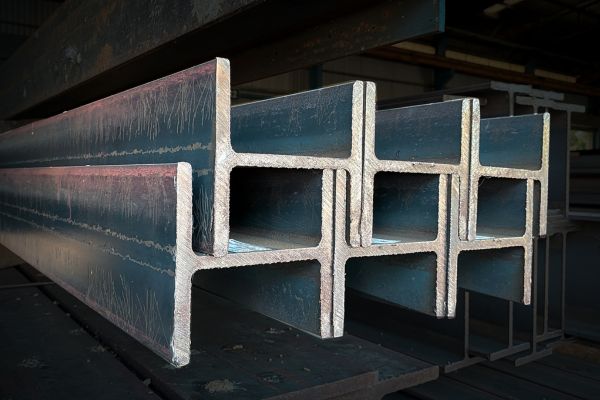

Elevate Your Architectural Projects with He-Max Industrial’s H-Beams

A reputable brand in steel products, He-Max Industrial Corporation is a trusted industrial steel supplier known for delivering high quality and reliability. Among its best offerings are He-Max’s H-Beams, which are crucial components of contemporary architectural designs. These premium steel beams are engineered for exceptional strength and durability, providing outstanding foundational support that ensures stability and safety, even in the most ambitious constructions. Their versatility makes them ideal for projects ranging from towering skyscrapers to expansive bridges.

Because of He-Max Industrial’s dedication to innovation and client satisfaction, every product satisfies exacting requirements, providing architects and builders with peace of mind. Upgrade your projects with H-Beams, which offer exceptional performance together with enduring dependability.

For knowledgeable advice and specialized solutions that complement your architectural vision and contemporary construction needs, contact He-Max today.

For more information or inquiries, feel free to contact us at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial