Sheet piles are long, interlocking panels made of steel or concrete, used for soil retention, foundation support, and water control. Various types of construction sheet piling are available to meet specific project needs, such as resistance to corrosion, ease of installation, or strength for deep, high-pressure applications in different environmental conditions.

Choosing the right beam type for a project ensures safety, cost-efficiency, and structural integrity. The right beam provides the necessary support and durability to meet the project’s specific load, span, and environmental needs, ensuring long-term performance and stability.

Structural Differences Between U-Type and Z-Type Sheet Piles

Understanding the structural differences between U-type and Z-type sheet piles is essential for selecting the right option based on project requirements like strength, durability, and installation conditions.

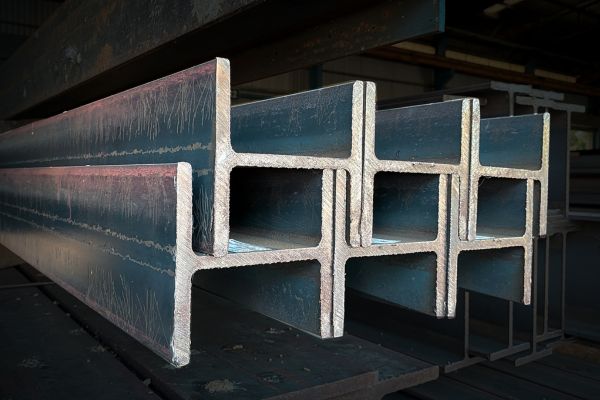

U-Type Sheet Piles

U-type sheet piles feature a “U” shaped interlocking design, offering strong structural stability and resistance to lateral forces. Their design ensures efficient load distribution, making them ideal for projects like retaining walls or riverbanks that require durable, long-lasting barriers. The interlocking edges enhance strength, reducing the need for extra support. With adjustable wall thickness to meet project needs, U-type sheet piles are well-suited for medium to heavy load-bearing applications. Their versatility makes them a go-to choice for infrastructure projects where stability and environmental resistance are key.

Z-Type Sheet Piles

Z-type sheet piles feature a Z-shaped profile that provides superior bending strength and capacity. Their unique design improves interlocking and alignment, creating a stronger, more continuous barrier against soil movement. Ideal for applications like deep foundations, retaining walls, and waterfronts, Z-type sheet piles resist lateral stresses effectively. Their interlocking feature also simplifies installation, ensuring a stable, secure structure. With enhanced durability and higher bending strength, Z-type sheet piles are built to perform reliably in demanding conditions.

Typical Applications of U-Type and Z-Type Sheet Piles

U-type and Z-type sheet piles are common types of steel sheet piles used in construction projects that require strong, durable barriers. Z-type sheet piles provide extra strength for deep foundations, retaining walls, and flood protection, ensuring long-term stability, while U-type sheet piles are ideal for general marine and waterfront applications.

U-type sheet piles are used in various applications, including:

- Temporary Walls: Affordable, quick solutions for creating temporary barriers on construction sites.

- Excavation Support: Effective for stabilizing excavations and preventing soil movement.

- Light-Duty Applications: Well-suited for tasks like erosion control or small retaining walls in less demanding environments.

- Waterfront Protection: Commonly used for small-scale waterfront projects or marine walls in areas with moderate water exposure.

There are several uses for Z-type sheet piles, such as:

- Permanent walls providing long-lasting structural support

- Seawalls designed to protect against coastal erosion

- Heavy-duty constructions that need enhanced strength and durability

- Deep foundation systems for areas with high load requirements

- Retaining walls for soil and water containment in challenging conditions

- Flood defense barriers offering increased resistance to water pressure

When to Choose U-Type vs. Z-Type Sheet Piles

When choosing between U-Type and Z-Type sheet piles, several factors should be considered to ensure the right fit for your project.

A. Project Type: Z-Type piles are ideal for challenging projects like deep foundations or heavy-duty structures requiring extra strength, while U-Type piles are better suited for general applications, such as shoreline structures.

B. Load-Bearing Requirements: Z-Type piles provide greater strength and are designed for high-load applications like sheet piling retaining walls or flood barriers. U-Type piles, while not as strong, are typically sufficient for lighter, less demanding applications.

C. Cost Considerations: Z-Type piles tend to be more expensive due to their higher material requirements and greater strength. U-Type piles, on the other hand, are more affordable and ideal for projects with lower strength and load demands. The key is finding a balance between strength requirements and budget constraints for the best solution.

Here’s a table that outlines the pros and cons of using U-Type and Z-Type sheet piles:

| Factor (Pros) | U-Type Sheet Piles | Z-Type Sheet Piles |

| Strength | Suitable for lighter applications | Provides greater strength for high-load areas |

| Cost | More cost-effective, ideal for projects with lower load demands | Higher cost due to material strength and complexity |

| Ease of Installation | Easier to handle and install in most applications | Stronger, but may require more specialized installation |

| Durability | Adequate for general uses but less durable under high stress | Stronger and more durable for demanding and long-term projects |

| Factor (Cons) | U-Type Sheet Piles | Z-Type Sheet Piles |

| Strength Limitations | Not suitable for high-load or deep foundation projects | Not ideal for lighter applications due to higher cost |

| Applications | Less suitable for heavy-duty or specialized projects | May be over-specified for smaller, less demanding projects |

| Cost | May not offer long-term durability for heavy-duty uses | Higher initial investment for more demanding applications |

Benefits of Selecting the Right Sheet Pile for Your Project

One of the main benefits of choosing the right sheet pile for your project is cost-effectiveness. By selecting the appropriate type, like Z-Type for heavy-duty tasks or U-Type for smaller projects, you can avoid over-specifying and stay within budget. Matching material strength to actual load requirements helps reduce waste and unnecessary costs, ensuring greater efficiency throughout the project.

The proper sheet pile also improves long-term safety and durability. Z-Type sheet piles, for instance, offer strong structural integrity and resilience to environmental stress, making them perfect for high-load locations. Despite being less expensive, U-Type heaps are durable enough for situations that aren’t as demanding. The structure’s safety, lower maintenance costs, and improved overall performance are all ensured by carefully choosing sheet piles, which also helps to prevent future expensive repairs and downtime. Selecting the appropriate sheet pile over time promotes sustainability and project success.

Need the Right Sheet Pile? Choose He-Max for U-Type and Z-Type Solutions

He-Max Industrial Corporation, a trusted sheet pile supplier in the Philippines, offers a wide range of U-Type and Z-Type sheet piles for various construction needs. Whether you require cost-effective solutions for lighter projects or durable, high-strength options for more demanding applications, He-Max provides reliable products that ensure long-term performance and structural integrity.

He-Max provides top-notch sheet piling solutions, supported by knowledge and devoted customer service. For every project, no matter how big or small, the team guarantees the greatest results and direction.

For knowledgeable support, customized pricing, and sheet piling solutions, contact He-Max. Our staff is prepared to assist in making sure your construction project is successful and efficient.

For more information or inquiries, feel free to contact us at:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial