Metals are vital to the construction industry because they provide the strength and durability required to produce long-lasting structures. The proper selection of construction metals guarantees structural integrity and lifespan in everything from skyscrapers to bridges. The selection process considers elements like cost-effectiveness, strength, and resistance to corrosion.

Hardware companies, manufacturers, and contractors can make better selections if they are aware of the various kinds of building metals and their characteristics. The most popular metals used in building construction are examined in this guide, along with their main distinctions and how to choose the best one for a given application.

Common Types of Construction Metals

Choosing the right construction metal is crucial for ensuring structural stability, longevity, and cost-efficiency. Various metals offer different advantages, from high strength and durability to corrosion resistance and lightweight properties. Understanding the characteristics of each metal can help contractors and engineers make informed decisions based on project requirements. In this section, we explore the most used construction metals, their key features, and the best applications for each.

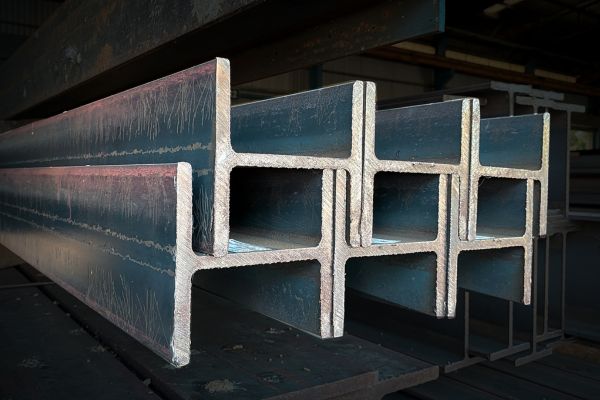

Steel

Steel is the most widely used metal in construction due to its high strength, durability, and versatility. It can withstand heavy loads and extreme conditions, making it ideal for structural frameworks, bridges, and industrial buildings. It’s also resistant to wear and tear and offers enhanced protection against rust.

There are different variations of steel:

- Carbon Steel: Offers high strength and affordability but requires protective coatings to prevent corrosion

- Stainless Steel: Known for its corrosion resistance, making it perfect for outdoor and marine applications

- Galvanized Steel: Coated with zinc to prevent rusting, commonly used in roofing and piping systems

Aluminum

Aluminum is a lightweight yet strong construction metal, offering excellent resistance to corrosion. This makes it a popular choice for outdoor structures, particularly in coastal areas where metal exposure to moisture is high. These are the common applications of this construction material:

- Roofing materials: Lightweight and durable for long-term use

- Windows and doors: Provide aesthetic appeal and weather resistance

- Cladding and facades: Used in modern architecture for energy efficiency and sustainability

Copper

Copper is widely used in construction due to its high electrical and thermal conductivity. It is naturally corrosion-resistant and develops a patina over time, adding to its aesthetic appeal. Common uses are the following:

- Electrical wiring: Ensures reliable electricity transmission in buildings

- Roofing materials: Durable and weather-resistant, commonly seen in historic and high-end structures

- Plumbing and piping: Prevents bacterial growth and ensures water purity

Iron

Iron, particularly cast iron and wrought iron, has been used in construction for centuries. Cast iron is strong but brittle, making it suitable for heavy-duty applications, while wrought iron is more malleable and used for decorative elements. Iron is typically useful for these:

- Bridges and industrial equipment: Provides structural support for heavy-duty projects

- Decorative railings and gates: They offer aesthetic value in traditional architecture

- Machinery and construction tools: Used for their durability in industrial settings

Other Notable Metals

- Titanium: Offers an impressive strength-to-weight ratio and excellent corrosion resistance, commonly used in aerospace and high-performance structures

- Brass and Bronze: Alloy metals used in specialized applications, such as fixtures, fittings, and ornamental details

Key Differences Between Construction Metals

Different construction metals serve unique purposes based on their properties, applications, and costs. Some metals are selected for their exceptional strength, while others are preferred for their corrosion resistance or lightweight properties. Understanding these differences helps engineers and builders choose the most suitable materials for their specific needs. In this section, we compare the most used metals based on strength, corrosion resistance, weight, cost, and ideal applications.

Strength & Durability: Steel vs. Aluminum vs. Titanium

Steel is the strongest among common construction metals, making it suitable for load-bearing structures. Aluminum is strong but significantly lighter, making it ideal for applications where weight reduction is crucial. Titanium, while expensive, offers a higher strength-to-weight ratio than steel, making it useful in high-performance applications.

Corrosion Resistance: Stainless Steel vs. Copper vs. Galvanized Metals

Corrosion resistance is a major factor in selecting construction metals. Stainless steel is highly resistant to rust and oxidation, making it ideal for coastal and industrial environments. Copper naturally resists corrosion and develops a protective patina over time. Galvanized metals, coated with zinc, offer cost-effective protection against rusting.

Weight Considerations: Aluminum vs. Steel

Aluminum is significantly lighter than steel, which reduces transportation and installation costs. It is ideal for roofing, facade panels, and structures that require weight reduction without sacrificing durability. Steel, while heavier, provides unmatched strength for structural frameworks and industrial applications.

Cost Factors: Budget-Friendly Options vs. Premium Metals

Steel is one of the most cost-effective construction metals, offering strength at an affordable price. Aluminum is more expensive than steel but provides better corrosion resistance and lower maintenance costs. Titanium is the most expensive option, but its durability and lightweight properties justify the cost in high-performance applications.

Applications: Best Metals for Specific Construction Needs

- Steel: Best for skyscrapers, bridges, and industrial structures due to their strength and durability

- Aluminum: Preferred for lightweight applications like roofing, window frames, and curtain walls

- Copper: Commonly used in electrical wiring, plumbing, and decorative elements.

- Titanium: Suitable for specialized high-performance projects, such as aerospace and marine structures

Choosing the Right Construction Metal for Your Project

Selecting the right construction metal involves considering various factors, including environmental conditions, load-bearing capacity, budget constraints, and longevity requirements. Contractors and developers should evaluate these aspects:

- Environmental exposure: For coastal or industrial settings, corrosion-resistant metals like stainless steel or aluminum are ideal.

- Load requirements: High-strength applications require steel or titanium for maximum support.

- Budget considerations: Steel and galvanized metals offer cost-effective solutions, while premium metals like copper and titanium are investment choices for long-term durability.

- Longevity: Investing in corrosion-resistant metals can reduce maintenance costs over time.

Industry Recommendations and Best Practices

- Structural Applications: Steel remains the top choice for major infrastructure projects.

- Electrical and Plumbing: Copper is the best material due to its high conductivity.

- Aesthetic and Decorative Uses: Brass and bronze add visual appeal to structures.

Get High-Quality Construction Metals from He-Max Industrial Today

He-Max Industrial Corporation is a trusted steel supplier in the Philippines, providing premium-grade construction metals for various applications. From steel beams to aluminum sheets, we offer a comprehensive selection of construction materials tailored to your project requirements. Our team of experts is ready to assist you in selecting the best metals that meet industry standards and project specifications.

Contact us today for reliable metal supplies that ensure durability and performance in every construction project:

- Trunkline: (632) 8275-3888

- Customer Service Hotline: 0917-1158387 (Globe) | 0925-8092196 (Smart)

Follow us on social media for updates and more industry insights:

- Facebook: https://www.facebook.com/hemaxindustrial